09/27/2019

A chilled water plant’s annual operating cost is a major contributor in a facility budget. Typical chilled water plants consist of multiple chillers, cooling towers, chilled water pumps, condenser water pumps, plate heat exchangers and water treatment equipment.

The chilled water is generated in the central plant and then transported through a piping network to cooling coils (air handlers), or to point of end-use in processes. Facility directors and energy managers are always chasing multiple goals - satisfying all the customers, maintaining a high-level of reliability and minimizing energy spends with varying demand and weather. Therefore, many modern plants employ a good chiller optimization package such as Hudson Technologies’ SMARTenergy OPS® in conjunction with Building Automation Systems (BAS) to optimize the chiller plants.

Chiller Plant Efficiency Driven by Cooling Tower Management

In a water-cooled chiller plant, cooling towers facilitate heat removal. Cooling towers are designed for peak summer conditions - high temperature and humidity. The efficient operation of a chilled water plant is highly dependent on cooling tower management. In practice, four cooling tower management strategies are applied, i.e., constant setpoint, seasonal reset, manual reset, and automatic reset. Application of a strategy is based on the chiller plant configuration and operation philosophy at a particular plant. Automatic reset is the most energy efficient strategy. It uses prevailing ambient conditions and the actual cooling load to continuously make setpoint changes.

The cooling tower energy consumption can have significant impact on the chiller plant performance. The chiller power requirement is dependent on Entering Condenser Water Temperature (ECWT) supplied by the cooling tower. This is explained further in sections below. As the Wet Bulb Temperature (WBT) drops, the chiller can be supplied with a lower ECWT. However, it must be noted the cooling tower approach (ECWT-WBT) increases for the same cooling load, cooling tower flow, and temperature range when WBT drops1. Temperature range is determined by subtracting the ECWT from Leaving Condenser Water Temperature. If the ECWT is set close to WBT without considering the variation in approach, it will be harder to meet the setpoint, which results in higher cooling tower energy consumption. Hence, it is important to manage ECWT in order to get optimum chiller plant performance.

The Impact of Condenser Water Pumps

In a refrigeration cycle, the chiller efficiency is commonly rated in kW/ton. The term is defined as the ratio of the compressor work in kW to the cooling load in tons. The lower the kW/ton – the higher the efficiency is for the chiller.

As the ECWT drops, the pressure in the condenser drops resulting in lower chiller compressor power while the cooling load remains the same. This results in lower kW/ton. Condenser water pumps are an integral piece of the puzzle when optimizing a chiller plant. There are several plant configurations that exist. If all the pumps are fixed-speed pumps and run continuously, their power consumption will not affect the optimum power requirement. However, in the case of Variable Frequency Drive (VFD) pumps, the pump power may vary, contributing to an energy trade-off between chillers, fans, and pumps, which makes it difficult to optimize the system.

Variation in load produces variation in heat rejection and flow for a condenser water pump. For simplicity of analysis for this article, it is assumed that within normal operating ranges, a VFD pump will not have significant energy trade-off with chiller or fans.

ECWT Reset Strategy Relatively Easy and Effective

An ECWT reset strategy represents one of the most effective and easily implemented energy efficiency measure for a chiller plant. The controls are designed to maintain the ECWT as low as feasible. This allows the condenser to operate at a lower pressure and reduces the overall lift delivered by the chiller compressor. The lift is the difference between condenser saturation temperature and evaporator saturation temperature, which drives the chiller efficiency.

When WBT drops, it is possible to reduce the condensing temperature thereby reducing lift. As a rule of thumb, each degree reduction in ECWT results in a 0.5% increase in chiller efficiency for safe operating range temperatures. 2

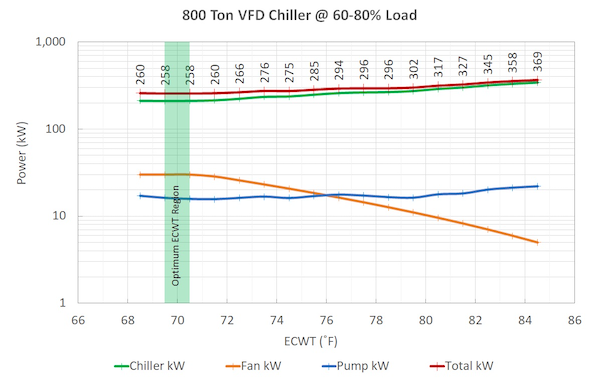

As discussed, with reduction of ECWT, the chiller power consumption continually reduces due to reduced lift. However, the cooling tower fan power requirement gradually starts to increase as fans are tasked with operating closer to full speed. This results in the total power requirement reducing up to an optimum ECWT setting, and then rising again as the tower fan power requirements rise with dropping ECWT very close to WBT. The ECWT should be maintained to achieve the minimal total kW (chiller kW + tower fan kW + pump kW) for the most efficient chiller plant operation. This sweet spot can be seen in Figure 1.

Figure 1: Depicted is the ECWT sweet spot for minimal power consumption.

An important precaution here is to not let ECWT drop beyond optimal when the load on chillers is high. This can lead to refrigerant stacking, a situation where there is abnormal accumulation of refrigerant in the chiller condenser preventing the refrigerant’s ability to flow back to the evaporator, and ultimately resulting in loss of cooling capacity.

Automated ECWT Controls Reduce Energy Consumption

Hudson Technologies has developed a smart ECWT control that incorporates a continuous reset strategy to optimize the cooling tower setpoint and reduce the overall system energy consumption.

The cloud-based SMARTenergy OPS system is a unique chiller optimization platform that continuously analyzes the chillers data for different faults and alarms to diagnose serious issues in the cooling systems. The diagnostics offered provide actionable insights, which if acted upon in a timely manner, can save significant amounts of energy costs.

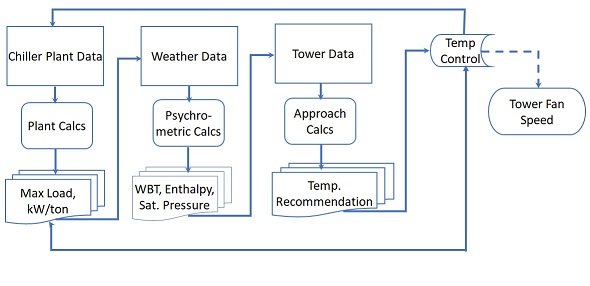

The ECWT control avails data from three sections of the plant, i.e., chillers, cooling towers, and the weather station. Once this data is available, the algorithm goes through calculations to determine recommended temperature, which in turn, is passed on to the local BAS. The integrated BAS then goes through appropriate sequence of actions to modify fan speeds, etc., to achieve the desired setpoint. The algorithm is designed to continuously check and optimize the setpoint to get the lowest kW/ton for the plant. The architecture of the ECWT is shown in Figure 2. The algorithm continuously searches for better efficiency through a heuristic method developed for the proprietary platform.

Figure 2: Shown is the SMARTenergy OPS ECWT control architecture.

Implementation of the ECWT control through SMARTenergy OPS is easily integrated with any kind of existing BAS, or it can be installed as a standalone system. With an existing BAS system, ECWT control can achieve advisory, or fully automated control with operator override as desired. It can also complement existing analytics systems to achieve optimized ECWT setpoints with respect to chiller performance.

Control Strategy Saves Energy at Aerospace Plant

The benefits of an ECWT reset strategy can be demonstrated using a case study.

An aerospace manufacturing plant in the Southwestern United States uses four chillers to supply chilled water for process as well as comfort cooling demand. The total cooling capacity of the plant is 3,700 tons and is setup as a traditional primary-secondary loop configuration. The chilled water setpoint is maintained at 40 °F. The energy baseline in the first year shows total chilled water system consumption of 6.8 million kWh for a cost of $479,000.

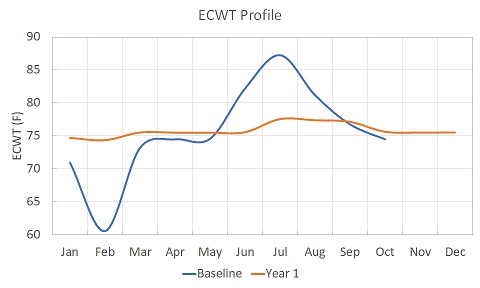

There are seven cooling towers supplying cooling water to a common header. The towers are interconnected and can supply cooling water to any of the four plant chillers. Based on the data collected with SMARTenergy OPS, it was observed that ECWT supplied from the cooling towers averaged 80 °F.

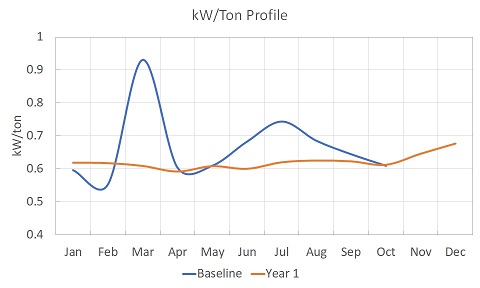

The optimization platform recommended dropping the ECWT on the cooling towers to 75 °F. Necessary steps were followed to drop the overall system ECWT down on the cooling towers when the weather permitted. As the ECWT is reduced, there is a reduction in the kW/ton of the chiller as expected due to overall reduction in chiller compressor lift. Hence, implementation of this strategy that aims to keep condenser water temperature at its optimum levels led to drop in kW/ton. Figures 3 and 4 show the improvement in the kW/ton profile. As the weather cools, the load on the chillers drops down leading to an increase in kW/ton.

Figure 3: An ECWT profile for monitored chillers.

Figure 4: A kW/ton profile for monitored chillers.

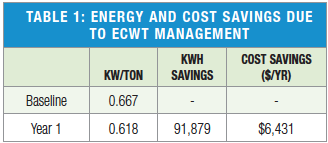

Substantial improvement is seen during summer months where the plant did not manage the ECWT. For the same months on the kW/ton profile significant reduction in power consumption can be noticed. During the base-lining period, the plant averaged 0.667 kW/ton whereas after implementation, the data analysis showed the plant averaged 0.618 kW/ton. Details are shown in Table 1.

Automated ECWT Reset Strategy Advantages Add Up

There are multiple benefits to the use of an automated ECWT reset strategy platform, including:

- The dynamic reset obtained with consideration of weather and plant load eliminates the need for the plant operators to constantly monitor and manually adjust the cooling tower setpoint

- Automated control can free up operators’ time to focus on other tasks to improve overall savings.

- This strategy represents the single biggest potential opportunity to maximize chiller energy efficiency – every degree reduction in the condensing water temperature reduces chiller energy consumption by 1 to 2 percent.

About Hudson Technologies

Hudson Technologies, Inc. is a refrigerant services company providing innovative solutions to recurring problems within the refrigeration industry. Its products and services are primarily used in commercial air conditioning, industrial processing and refrigeration systems, and include refrigerant and industrial gas sales, refrigerant management services, consisting primarily of reclamation of refrigerants and RefrigerantSide® services, consisting of system decontamination to remove moisture, oils and other contaminants. In addition, the company’s SMARTenergy OPS® service is a web-based real time continuous monitoring service applicable to a facility’s refrigeration systems and other energy systems. Its Chiller Chemistry® and Chill Smart® services are also predictive and diagnostic service offerings. It also participates in the generation of carbon-offset projects. The company operates principally through its wholly owned subsidiaries, Hudson Technologies Company and Aspen Refrigerants, Inc., formerly known as Airgas-Refrigerants, Inc. For more information, visit www.hudsontech.com.

All charts courtesy of Hudson Technologies, Inc. The authors would like to express their sincere gratitude to Mr. Derrick Shoemake, IT Lead, Hudson Technologies Company, for his help on the development of Entering Condenser Water Temperature Reset Strategy.

To read similar cooling controls articles, visit https://www.coolingbestpractices.com/technology.

1 ASHRAE Handbook 2008 – HVAC Systems and Equipment, “Cooling Towers”, Ch.39, pp.39.13-15, Atlanta, GA, 2008

2 Hamilton, G., “Optimizing Hospital Chiller Plants”, Engineered Systems, Vol. 34, No.7, pp 24-29, July 2017.