10/30/2018

Since 2002, Energy Trust of Oregon have saved and generated 728 average megawatts of electricity and 52 million annual therms of natural gas. This is enough energy to power Multnomah and Washington counties while heating Deschutes County homes. ETO has saved enough energy equal to the output of a power plant and reduced reliance on fossil fuels. In total, they have invested $1.5 billion to save customers more than $6.9 billion on their energy bills over time. They have also added $5.7 billion to the local economy, including $1.7 billion in wages, $312 million in small business income and employment equal to 4,700 full-time jobs lasting a decade. Carbon emissions have been cut by nearly 20 million tons, equal to removing 3.5 million cars from the roads for a year. Efficiency remains the least expensive energy resource Oregonians can buy. This affordable energy supply helps utilities avoid investment in new and more expensive energy resources. The following articles are just two examples of such success stories.

Deschutes Enjoys a Long Draft of Energy-Cost Savings

Deschutes Brewery has a long history of engaging in energy-efficiency projects, and is reaping the rewards: $34,500 in estimated annual energy cost savings.

In 2004 when Deschutes Brewery went through a major expansion of its Bend brewing facility, the brewery made sure its new 40,000-square-foot warehouse was a model of efficiency. Built to exceed Oregon energy code, the well-insulated concrete warehouse maintains a 64° F temperature year-round by taking advantage of free cooling available from Central Oregon’s cool night air. Both the warehouse and the packaging line have low-wattage T5 high-output fluorescent lighting and occupancy sensors.

Deschutes’ brewing operation is fueled by energy-efficient boilers with stack economizers that reclaim heat from the ue gas and loop it back into the feed water. In addition, a vapor condensing heat exchanger on the brew kettle helps preheat the next batch of brewing water. Deschutes also replaced four inefficient glycol pumps on its chilled water system with two new efficient glycol pumps with variable frequency drives. “These new pumps help us to produce more beer with less energy,” said Ron Shoemaker, maintenance manager, Deschutes. “They boost product quality, and they cool our fermenters faster, so we get more tasty beer out the door.”

|

Energy-Saving Improvements

Estimated Savings

Financial Analysis

|

The brewery has worked closely with Energy Trust over the years, receiving a total of $36,500 in cash incentives to support nine energy-efficiency projects. An effort that reaped considerable estimated savings—more than 181,000 kilowatt hours annually—resulted from participating in Energy Trust’s custom operations and maintenance offer in which Energy Trust experts helped identify and repair compressed air leaks and set up an internal leak detection program so the savings persist.

Energy Trust also helped Deschutes outfit its Portland brewpub with a high-ef ciency heating, ventilating and air conditioning system as well as energy-efficient foodservice equipment ranging from an infrared gas fryer to a high-efficiency freezer.

Deschutes is quick to share its experience with others. “Oregon breweries are a tight group,” said Shoemaker. “We take advantage of what each of us has learned about making great beer using less resources.”

To learn more about technical services and cash incentives available to eligible businesses located in the Energy Trust of Oregon service territory for energy-efficient equipment upgrades, please visit www.energytrust.org/industry.

Holladay Park Plaza Upgrades Chiller and Trims Annual Energy Costs

Life at Holladay Park Plaza, a continuing care retirement community in Portland, is geared toward living life to the fullest. And comfort is a key ingredient. When the 50 year-old chiller that serves Holladay Park’s 16-story Tower Building could no longer keep up with demand, it was a problem that needed prompt attention. Temperatures were inconsistent, particularly during spring and fall when the 382,000 square-foot building went from heating to cooling in the course of a day. In the heat of the summer, the chiller couldn’t deliver comfortable temperatures to Holladay Park’s 270 residents.

Having worked with Energy Trust of Oregon on ten previous energy improvements, Holladay Park decided to add a new chiller to its list of improvements.

|

“We’ll save over $16,700 in utility bills each year because we upgraded to a new energy-efficient water-cooled, magnetic- bearing centrifugal chiller that keeps our 382,000 square-foot building at a consistent temperature all day long. Plus, Energy Trust gave us over $47,900 in cash incentives just for upgrading.” - Marty Rowe, Director Facility Services, Holladay Park Plaza Assisted Living |

Energy Trust arranged for a technical study to outline the costs and savings of different energy-efficient chiller options. After Holladay Park made its selection, the retirement community received more than $47,900 in Energy Trust cash incentives to help offset the cost of the project.

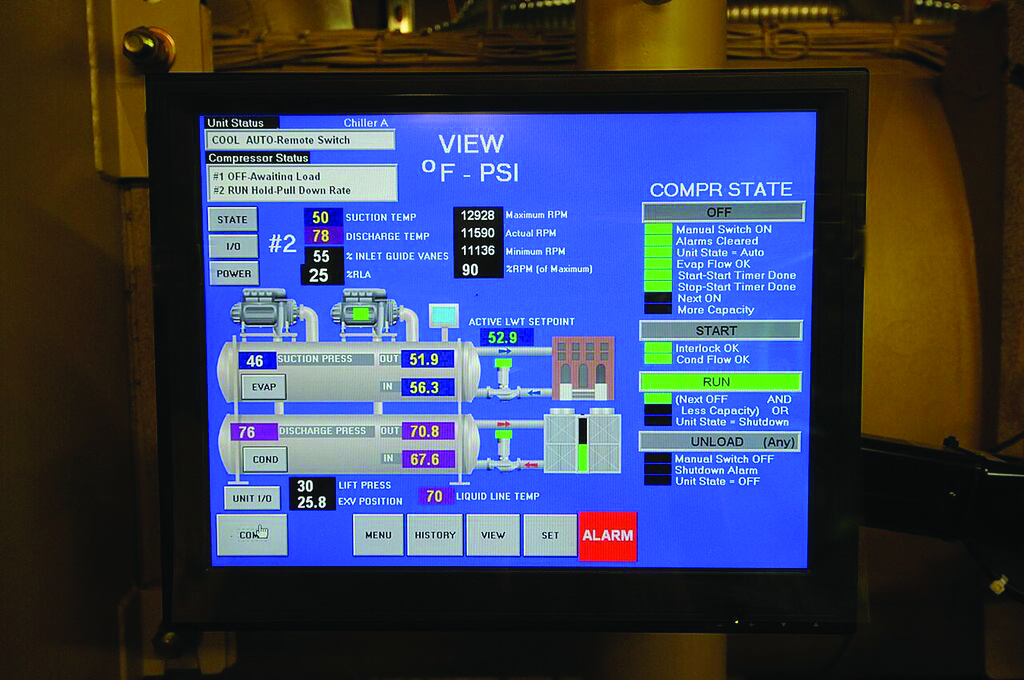

The new 375-ton, water-cooled, magnetic- bearing centrifugal chiller has a variable frequency drive and sophisticated direct digital controls. Unlike the old chiller, it excels at part-load performance—sensing outside and inside temperatures and precisely adjusting output to match demand. Now, residents are comfortable even if the outside temperature swings from hot to cold in a matter of hours. “With the old chiller, we had to try to make those adjustments manually, often with limited success,” said Marty Rowe, director of facility services, Holladay Park. “The new system is so much more efficient and responsive. It also requires less maintenance and is quieter.”

The chiller’s electronic controls allow facilities personnel to monitor the system online and make adjustments from any location. With the chiller located two levels below grade, removing the old chiller and installing the new model posed a logistical challenge.

Click here to enlarge

The Solution?

Energy Trust trade ally contractors dismantled and removed the old equipment. They then took apart the new chiller and reassembled it in the mechanical room to meet their fast-track schedule.

Now, all areas of Holladay Park Plaza—from resident apartments to offices, restaurant and swimming pool—are comfortable year-round, and Holladay Park is saving an estimated $16,700 on annual energy costs.

|

Holladay Park Assisted Living PROJECT-AT-A-GLANCE Equipment Installed

Financial Analysis

Estimated Annual Savings

|

To learn more about technical services and cash incentives available to eligible multifamily properties located in the Energy Trust of Oregon service territory for energy-efficient equipment upgrades, please visit www.energytrust.org/multifamily.

All photos courtesy of Energy Trust of Oregon.

To learn more about energy efficiency for industrial facilities, visit www.energytrust.org or call 1.866.368.7878.

To read similar Energy Incentives articles visit coolingbestpractices.com/energy-manager/utility-incentives.