Heat Exchangers

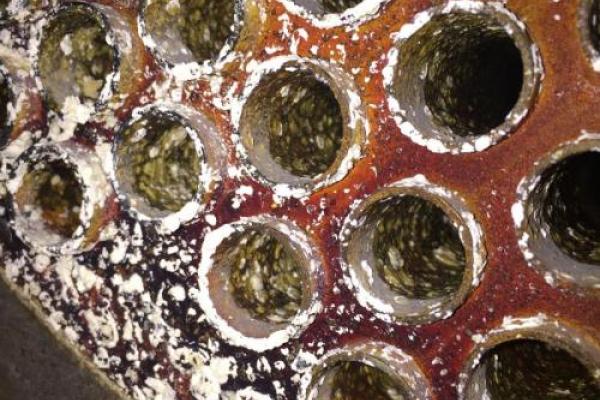

We are certain it comes as no surprise to the readership of this journal that a third of the total energy end use for commercial buildings in the U.S. is consumed by HVAC (DOE 2008). Chillers are usually the single largest individual user of electricity in commercial and institutional HVAC facilities. Maintenance and engineering managers have three primary options to improving chiller performance: replacement, control strategies and maintenance. As chillers are required to reject heat to complete the vapor-compression cycle, a condenser heat exchanger is used which allows heat to migrate from the refrigerant gas to either water or air. Heat transfer has the greatest single effect on chiller performance.

A total of 1,875 exhibitors spread across 527,520 square feet, and 120 free educational sessions drew 48,034 total attendees. Driven by decarbonization and green transition megatrends, this event highlighted the global refrigerant transition; adoption of heat pumps; integration of building automation systems and AI; and optimization of the energy/water nexus in applied equipment. This article recaps the response and innovation from manufacturers of chillers, cooling towers and related equipment.

[ Read Full Story ]

This article examines challenges with phosphorous-based programs, key factors to controlling cooling water chemistry and the advantages of phosphorous- and zinc-free cooling water treatment technology.

[ Read Full Story ]

Ultrasonic leak detection has been used for a variety of applications ranging from energy reduction by locating compressed air leaks to quality assurance inspections such as locating wind noise and water leaks in automobiles. The secret to success is to understand the nature of what type of leak produces a detectible ultrasound and what does not, along with the techniques that can be used for effective leak identification. Once understood, there are instances where the limits of detection can be enhanced to help locate a leak in difficult situations.

[ Read Full Story ]

When the topic of discussion is making ice cream, the first thing that comes to mind isn’t heat, but at Nestlé’s Ice Cream factory in Tulare, California, heat is recovered from air-cooled air compressors to heat process water.

“Right out of the gate, everything is pneumatic,” explains Tom Finn, Project Engineer with Nestlé Ice Cream Division. “Air cylinders and air driven motors, the process piping valves which divert, route, stop/start, and mix process fluids, our packaging machinery including rejection, cleaning and vapor removal processes, all of these rely on compressed air.

[ Read Full Story ]

As the population continues to grow in the United States, industrial water use will need to continue to fall to help offset the increases in public-supply water use. Water-cooled compressed air systems provide an opportunity for sustainability managers to reduce associated cooling water consumption and costs. If switching to air-cooled air compressors is not possible, understanding the costs and the alternative types of liquid cooling systems is important.

[ Read Full Story ]

The rise in energy prices is an unwelcome reality in today’s manufacturing and business environment. And while the rate of price increases for natural gas, heating oil and electricity may vary from year to year, the upward trajectory is clear. Energy cost reduction strategies are vital to staying competitive. Compressed Air Best Practices® Magazine recently discussed heat recovery, from industrial compressed air systems, with the Compressed Air and Gas Institute’s (CAGI) Technical Director, Rick Stasyshan and with CAGI member – Werner Rauer of Kaeser Compressor. Their inputs should provide you with some insight in energy-saving technology.

[ Read Full Story ]

When compressed air is generated, heat is inevitably produced as a by-product. Anyone looking to enhance efficiency can use this heat and increase the efficiency of compressors to about 95 percent as a result. To achieve this, there are easy-fit heat exchangers which can be fitted to existing air compressor stations. This investment often pays for itself within less than a year.

[ Read Full Story ]

There are six basic types of cooling systems that you can choose from to meet the cooling needs of your load. Each one has its strengths and weaknesses. This article was written to identify the different types of cooling systems and identify their strengths and weaknesses so that you can make an informed choice based on your needs.

[ Read Full Story ]

Compressed air systems are present in almost all industrial processes and facilities. They have been correctly identified as an area of opportunity to reduce electrical (kW) energy costs through measures like reducing compressed air leaks and identifying artificial demand and inappropriate uses. Water-cooled air compressors can also be significant consumers of water and reducing these costs can represent a second area of opportunity.

[ Read Full Story ]

Its simple physics that compressing air gives off heat. The heat energy is concentrated in the decreasing volume of air. To maintain proper operating temperatures, the compressor must transfer excess heat to a cooling media before the air goes out into the pipe system. As much as 90 percent of that heat can be recovered for use in your operation. If you can supplement or replace the electricity, gas or oil needed to create hot water for washrooms, or direct warm air into a workspace, warehouse, loading dock, or entryway, the savings can really add up.

[ Read Full Story ]