10/31/2018

Given that HVAC systems typically account for 44% of commercial buildings’ energy consumption1, HVAC optimization should be a priority efficiency upgrade after lighting improvements and other low-hanging fruit. Full-scale HVAC optimization typically reduces energy usage and costs by 20 to 40%, improves system reliability by operating equipment more efficiently and at optimal temperatures, ensures consistently healthy air quality and building comfort, and reduces a building’s carbon footprint.

The term “optimization” is often applied loosely to various types of controls and upgrades in the HVAC world, but truly optimizing an HVAC plant means automatically controlling HVAC equipment as a holistic system, around the clock, to use the least amount of energy without sacrificing building performance. The chillers, boilers, air handling units, ductwork, diffusers, thermostats, sensors, and more must work together like a well-coordinated team to yield the full benefits. In addition, optimization software should continually capture and analyze system data to determine additional measures that will improve efficiency and provide performance metrics.

Optimization can be a significant project, but given the immediate savings and a typical payback period of less than four years, it makes good sense to undertake it.

Well-designed optimization projects can minimize resource use in chilled water plants, resulting in immediate savings and significant contributions to sustainability goals.

What usually holds people back from pursuing optimization is one or more of three common barriers: concerns about optimization in sensitive environments, uncertainty about results, and cost accounting. Facility executives can address each of these issues with careful project planning and mitigation strategies.

Sensitive Environments

Facility operators are understandably hesitant about optimizing HVAC systems in environments where maintaining precise temperatures and other climate factors is essential. In a hospital, for example, spaces like operating rooms and emergency rooms can’t go offline at any time. Project leaders can mitigate risk by detailing testing methodology, backup plans in case of performance problems, and the best low-occupancy times for implementation and testing.

Air quality, freshness, and humidity also are important in sensitive environments, and ultimately an optimization project should give facility operators better control of these factors. As for temperature, optimization will improve consistency by preventing the heating system from fighting the cooling system, creating instability and energy waste.

The implementation process may also reveal issues that have been masked. The project may be an opportunity to upgrade air filtration, for example—that’s not affected by optimization, but it is important to establishing good air quality.

Uncertain Results

It’s hard to justify the budget for an optimization project if you can’t verify predicted results—and I’ve seen savings estimates produced at the beginning of an optimization project end up off by up to 50%. This can happen when the facility doesn’t have a believable energy baseline, which renders estimates uncertain. It can also happen when the optimization project does not build in a continuous improvement process. Another factor that can depress savings is a lack of buy-in from facility operators, which results in their operating the system manually, or even removing it from optimization entirely.

Project leaders can overcome these challenges by taking these steps:

- Before moving forward with a project, correlate all power draws with the facility’s utility bills, vet the energy model the vendor employs, and understand the assumptions it is based on.

- Make sure all HVAC equipment is modeled and its energy impact is accounted for so that you don’t end up doing something like optimizing the chilled water system to save energy on the chillers, but then causing the air handler fans to ramp up to counter an overly ambitious chilled water reset, resulting in more fan energy usage across your building.

- Make sure there’s a measurement and verification plan in place to prove the actual results, verify that continuous monitoring is part of the project, and budget for at least a year of post-project follow-up and monthly energy reports.

- Have an internal champion who understands where the savings come from and the technology involved, and who has seen it in action. This is especially important when the impetus for optimization is coming from outside the on-the-ground facility management staff.

- Share new techniques and practices with operators and facilities engineers, and provide training and possibly visits to other optimized facilities as early in the project as possible. In addition to moving the project forward, this kind of orientation can generate feedback on optimization factors that might be overlooked without the input of the people who operate the building.

Cost Accounting

Project approvers don’t always have a holistic view of all the work that various players in the project have to do, how each aspect will affect the outcome, and how to cover costs. You may need to balance up-front capital costs with optimal ROI—sometimes you have to spend more initially to get the desired ROI. Consider sources of funding other than your capital budget—for example, financing via your local utility or another entity based on anticipated savings.

Older buildings and older equipment can increase costs, as it may be necessary to replace or upgrade components. A phased approach can make this financially feasible. For instance, you could deploy software alone to achieve partial optimization, and then use the savings over time to fund mechanical equipment and system upgrades that will fully optimize your system. To do this effectively, establish a priority order based on savings potential, with a focus on easy pickings, such as setpoint resets and cooling tower improvements, before spending hundreds of thousands of dollars on a new chiller.

The most successful optimization projects grow from early collaboration with facility operators, controls contractors and equipment vendors, as well as training on the technology. A good optimization provider will provide an analysis of the facility’s current operation, how efficient it is, and how it will operate after the project.

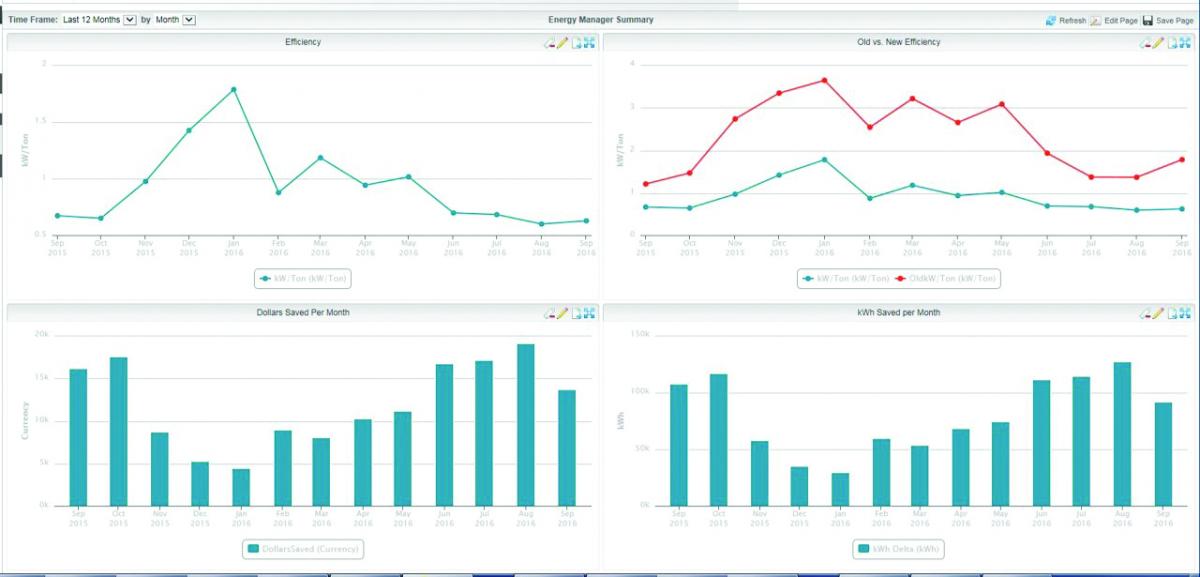

A clear method of presenting energy usage and savings data is essential to maintaining a successful HVAC optimization project. Click here to enlarge.

A well-defined project plan will deal not only with the installation and integration of the optimization technology, but also all required testing, post-project measurement and verification, and data analysis for further system efficiency improvement. With all these elements in hand, facility executives can be confident that an optimization project will deliver maximum savings and operational benefits at an appropriate ROI.

1U.S. Energy Information Administration 2012 Commercial Buildings Energy Consumption Survey: Energy Usage Summary: March 2016. (2016, March 18). Retrieved August 13, 2018, from https://www.eia.gov/consumption/commercial/reports/2012/energyusage/

|

About the Author

Ian Dempster is Senior Director of Product Innovation at Optimum Energy and a certified energy manager (CEM). He directs multiple simultaneous R&D projects, drawing on a 16-year engineering career that spans three continents.

All photos courtesy of Optimum Energy. For more information, please visit www.optimumenergyco.com.

To read similar Cooling System Assessments visit coolingbestpractices.com/system-assessments.

Ian Dempster is Senior Director of Product Innovation at

Ian Dempster is Senior Director of Product Innovation at