10/31/2018

A common misconception in plastics injection molding is that coolant temperature is the one true path to achieve productivity and profitability. The reality, however, is that turbulent flow is the primary force behind efficient cooling and a key driver in the ability to achieve operational efficiencies, increase profits and consistently produce high quality products.

Here’s what to know about turbulent flow in plastics molding, as well insight into the most recent advances in technology that allow processors to monitor and control flow, in addition to temperature.

Colder is NOT Always Better

Although precise temperature control is always critical, don’t assume necessarily that lowering the chiller temperature will help to reduce cycle times. Lowering a chiller operating temperature can have many negative effects.

Most chillers are rated (in tons) for 50˚F supply to process, which is just an arbitrary standard that the North America domestic plastics industry has accepted over the years. An important “rule of thumb” is that the capacity of a chiller is reduced by 2% per ˚F below 50˚F. So, if the temperature is reduced by 5˚F to 45˚F, the chiller capacity is lowered by 10%. This can cause the need to increase chiller capacity in order to properly cool the mold.

On the other hand, raising the temperature above 50˚F will, likewise, increase capacity. For example, increasing the temperature to 65˚F (the typical maximum) will result in an additional 30% capacity. This means more capacity for cooling additional molds using the same chiller.

Another negative effect involves the necessity to use a glycol antifreeze solution, which is typically required for operation at or below ~47˚F. This has huge, multiple effects on heat transfer.

As an example, for a chiller to operate at 40˚F, the refrigerant temperature in the evaporator will typically be 30˚F – obviously below the water freezing point. In this case, a 25% ethylene glycol solution will be required (freezing point @ 11˚F), protecting the chiller down to ~20˚F below the evaporating temperature. The results are ominous for the heat transfer process and can result in a vicious circle.

- Chiller capacity is reduced by 7%.

- Mold cooling capacity is reduced by the same amount.

- Pressure drop (ΔP) is increased by 21%. This means more pumping capacity to achieve the same result. Also, the additional pump motor heat will reduce chiller capacity, over and above the reduction due to the lower operating temperature.

- The subsequent result of the above is increased energy cost.

Turbulent Flow IS Always Better

In addition to accurate temperature control, optimizing flow through a mold is critical and, quite often, results in decreased cycle times and increased product quality and repeatability, even after increasing chilled water temperature. There are three stages of flow – laminar, transient and turbulent. This depends on a dimensionless factor call Reynold’s Number, which, for straight pipe, is a function of fluid velocity, internal diameter, fluid density and fluid viscosity (“resistance” to flow). The “flipping” point to turbulent in straight, clean a pipe is defined as 4000, but much higher R values are usually sought for injection molds, considering factors like bubblers, channel geometry, circuiting (i.e. series v. parallel), etc.

Note that viscosity increases when using glycol, resulting in the need for increased velocity to compensate for this increased resistance. This, in turn, requires more pumping to achieve proper velocity, and so on – see vicious circle described above.

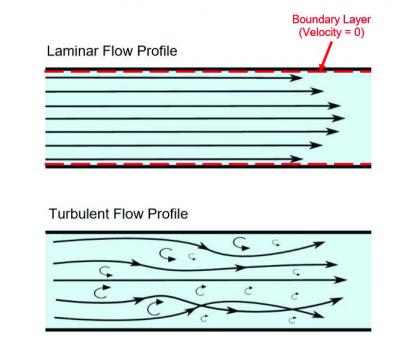

In laminar mode, a “boundary layer” forms at the pipe (cooling channel) surfaces – literally no flow along the perimeter of the cooling channels. This has the effect of insulation and impedes the heat transfer process. On the other hand, turbulent flow results in no boundary layer and is violent in nature, literally “scrubbing” the heat from the channel surfaces and carrying it away efficiently. Transient is an intermediate range between the two. Here is what the profiles look like:

The target for proper flow and, therefore, heat transfer, should be to limit the water temperature rise through the mold (ΔT) to 2˚F or less. This results in even and efficient cooling throughout the mold cavities and consistent part finish and quality, even (and especially) in multi-cavity tools. High turbulent flow is the way to accomplish this and is a function of analyzing the mold requirements, such as cooling load, ΔP, pump pressure required to achieve this low ΔT and, of course, proper pumping selections and the maximum chilled water temperature possible.

The results of this optimization of the heat transfer process through proper flow and temperature control are numerous.

- Cycle times and scrap are reduced.

- Product quality and consistency are improved.

- Energy is reduced due to maximizing the chilled water temperature.

- It’s often possible to handle additional molds with the same chiller because of the increased temperature, resulting in increased chiller capacity.

The Path to Optimization

The abovementioned factors assume a “clean” water system is utilized. Scale can change everything. For example, a 0.3 mm (0.012 inch) scale thickness on a channel surface will reduce heat transfer by as much as 21%. This can be applied also to any heat exchange surface, including those in a chiller.

As a result, a growing number of processors have turned to closed-loop process cooling systems to gain better control of turbulent flow and other process cooling parameters, given the need to increase operational efficiencies and improve margins.

One such system can be described as “decoupled” and involves a closed-loop central dry cooler (as opposed to a conventional open cooling tower) for cooling hydraulic heat exchangers, feed throats, air compressors, etc. and includes a water-cooled combination chiller/temperature control unit (TCU) located at each machine. This system uses heat exchangers and an adiabatic misting chamber to cool water circulated to it from the molding machines and machine-side units.

A decoupled system allows users to gain more control of pressure and flow, because each chiller/TCU is dedicated to a given molding machine. This eliminates problems with insufficient pressures and, therefore, flows at the machines typical of central chilling systems.

A Frigel Chiller/Temperature Control Unit

At each machine, the chiller/TCU leverages engineered high-flow process pumps to deliver consistent supply pressure and turbulent flow needed for that specific machine and each unique mold, as well as maintaining highly accurate temperature control.

The need for tighter control over pressure and turbulent flow has also driven advancements in chiller/TCU technologies.

Newer combination chiller/TCUs, for example, are equipped with variable frequency drives (VFDs) that allow a unit to develop only the necessary amount of water pressure differential and flow needed with the least amount of energy consumption. Some units also include digital flow meters, which enhance the ability to ensure (and record) accurate turbulent flow achieved to optimize each specific mold.

Most TCUs also feature user-friendly digital controls that make short work out of the necessary settings to ensure proper turbulent flow and temperature control from machine to machine and job to job. These controls also make it easy to monitor flow data and assess historical trends, to ensure consistency and repeatability.

Conclusion

Over the years, the importance of proper flow through a mold has become accepted, although this took quite some time. Pumps, whether they be in a chiller or TCU, must be carefully selected to achieve optimum turbulent flow. Inadequate pumping capability assuredly leads to laminar flow and poor heat transfer, resulting in poor cycle times, part quality problems, increased scrap and, ultimately, loss of productivity. Temperature is an important factor, especially temperature control accuracy, but temperature alone usually takes somewhat of a back seat to flow. It is also notable that these same principles apply to blow molding, extrusion and any other fluid heat transfer process.

About the Author

Al Fosco has a Master of Science degree from the University of Illinois, specializing in heat transfer and fluid dynamics. He has held many engineering, sales and management positions, first with AEC, followed by Conair, and is currently Marketing Manager for Frigel North America.

For more information please visit www.frigel.com.

To read similar Cooling System Assessment articles please visit coolingbestpractices.com/system-assessments.