01/28/2022

The Best Practices 2021 EXPO & Conference, held at the Schaumburg Convention Center near Chicago O’Hare International Airport, will be remembered as a welcome industry reunion - after having been forced to be apart during a time. The EXPO & Conference focuses on “Optimizing On-site Utilities Powering Automation.” Experts from all over the world convened to discuss compressed air, pneumatics, motors and drives, vacuum, aeration blower and chiller/cooling and water treatment systems.

Held November 2-4, 2021, this 3rd installment of the event continued to provide continuing education, certification and networking opportunities to equipment sales engineers, engineering firm and manufacturing plant personnel.

Peter Modrow, Nate Price, John Schmitt, David Andrews and Steve Hill (CompressAir) at the Sullair booth.

CAGI Education Committee Chair, Chad Larrabee delivering Opening Remarks at the Best Practices 2021 EXPO & Conference.

The publishers of Compressed Air Best Practices®, Blower & Vacuum Best Practices and Chiller & Cooling Best Practices magazines produced the three-day event. I would personally like to thank our sponsors and exhibitors, speakers, attendees and our Best Practices team members (Patricia Smith, Bill Smith, Kimberly Vickman, Patty Mackey and Clare Lamperski) whose amazingly positive and “can-do” attitude made the event possible.

The Certified Compressed Air System Specialist (CCASS) Exam

We are honored to have the Compressed Air and Gas Institute as the overall event Sponsor. We were pleased to offer CAGI’s relatively new Certified Compressed Air System Specialist (CCASS) Exam during the event. This proctored “pass/fail” exam is a part of CAGI’s personnel certification program providing a means of verifying the capabilities of professionals in the compressed air industry and for those maintaining/operating compressed air equipment. This exam has its’ own fee which folks paid directly to CAGI and our event offers these people a free EXPO pass. We’d like to recognize a sampling of the companies who sent professionals to take the exam.

- CASCO USA (a group of sales engineers!)

- WestRock (packaging solutions manufacturer)

- Flow Solutions, Atlas Machine, Arizona Pneumatic, Tunna Industrial

Robert Haseley, Jenny Oblock, Chad Larrabee and Jan Pingel at the CAGI booth (left to right).

The Conference

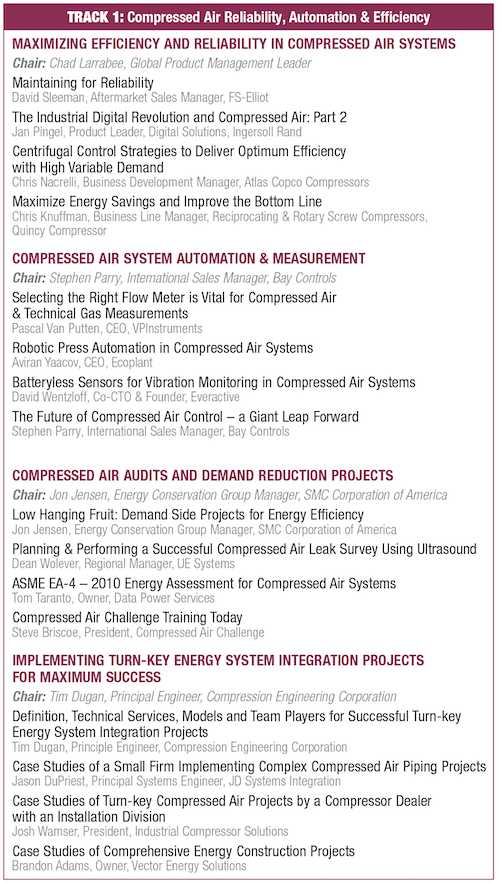

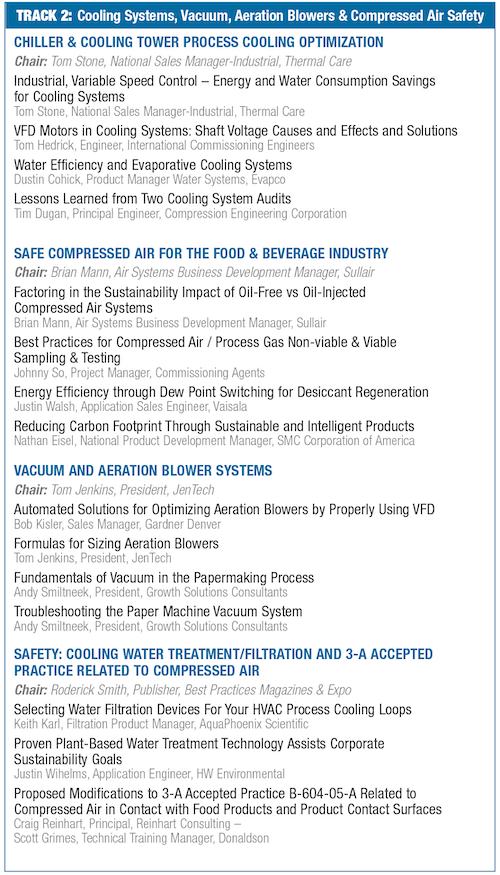

Conference registrants gain access to 100% of all the events at the three-day event. The Conference featured over 42 speakers sharing their expertise during Opening & Plenary Sessions, Track 1 on Compressed Reliability, Automation and Efficiency, Track 2: Cooling Systems, Vacuum, Aeration Blowers and Compressed Air Safety, and Compressed Air Challenge Level 1 Training.

The Opening & Plenary Sessions are open to all attendees including EXPO-only attendees and exhibitors. Held in “the big room with the stage”, the goal is to provide motivation and examples of the way forward for “Best Practices.”

Click to enlarge.

The two conference tracks provide a venue for experts to speak and to meet one another. Track 1 focused on Compressed Reliability, Automation and Efficiency while Track 2 zeroed in on Cooling Systems, Vacuum, Aeration Blowers and Compressed Air Safety.

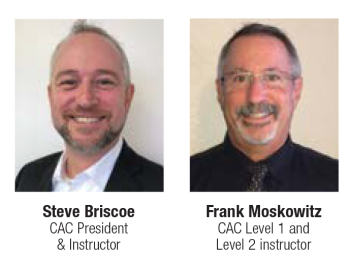

Formal Compressed Air Challenge Level 1 Training was provided by CAC President Steve Briscoe and by Instructor Frank Moskowitz. Attendance was excellent and it was scheduled in the afternoon so participants could attend the morning conference sessions.

Networking, Knowledge Sharing and New Technology at the EXPO

The EXPO took place during the afternoons of the first two days of the event. EXPO registrants can attend for only \$15 and are able to attend the Networking Events, the EXPO, the New Technology EXPO Classroom and participate in the Daily EXPO $1,000 Energy Treasure Hunt RAFFLE!

All attendees were treated to networking events including an Opening Reception and a fun Closing Party, at a local tavern, from which mysteriously the only record we have is from one of the shuttle bus rides back to the hotel.

At the EXPO, BEKO Technologies, a Diamond Sponsor of the event, displayed two DRYPOINT RA refrigerated dryers, a DRYPOINT XC heatless desiccant dryer, CLEARPOINT coalescing and particulate filters, BEKOMAT zero air loss condensate drains, QWIK-PURE and ÖWAMAT oil water separators and more. The second generation DRYPOINT XC heatless desiccant dryer (up to 2,800 scfm, from 80 – 7,250 psig) has a redesigned frame assembly. The new frame design supports both powder-coated vessels independently, so less material is required, decreasing the cost and weight of the unit. Next, the 800 scfm (up to 6,000 scfm) RA VSD Series refrigerated dryer is equipped with vertically-mounted aluminum heat exchangers, as all are BEKO refrigerated dryers. Regional Sales Manager-West Randall Corthouts said, “Because demand in compressed air systems often varies, the RA VSD is intelligently equipped with two VSDs on the scroll compressor and condenser fan to monitor the incoming conditions and adjust to meet the required cooling capacity of the refrigerant in the downstream air/refrigerant heat exchanger.”

A show highlight for me occurred when I ran into two long-time magazine readers from a major semiconductor manufacturer located in the southwest. I asked them what they were looking for on the EXPO floor and they answered, “We are looking for new air compressor technologies, the latest leak detectors and for a solution to a compressed air condensate problem our vendors haven’t been able to solve.” This last part intrigued me because they are very knowledgeable with compressed air – so I asked for more information and learned something new! I didn’t know the intercooler heat exchangers of centrifugals are under negative pressure when off-loaded. The problem is their standard condensate drains, requiring positive pressure, don’t work until pressure is restored-but by then the condensate has already been swept downstream.

I knew enough to understand the problem and suggested we visit the BEKO booth where it turned out BEKO Technologies President Tilo Fruth started his career in precisely this area of “custom-engineered drain applications”! I left with the good feeling of knowing my friends from Texas were on their way to their problem being solved at our EXPO. This was a reminder to me that often the most important asset at a trade show booth is the knowledge of the exhibitor.

Josh Borrego and Tilo Fruth, from BEKO Technologies, solving a challenging centrifugal air compressor condensate problem for two EXPO attendees from a major semiconductor manufacturer.

Mikropor, a leading manufacturer of compressed air treatment systems and atmospheric air filtration solutions, is pleased with the recent growth of its organization. With three hundred new employees joining the team in 2021 (1,100 total), 3.5 million ft2 of production space at headquarters in Ankara, Turkey, a 200,000 ft2 facility in Michigan City, IN and other manufacturing operations across the globe, Mikropor anticipates another 35 years of creating “Tomorrow’s Technology” since its inception in 1987. Mikropor’s portfolio ranges from several refrigerated and desiccant dryer technologies, compressed air and atmospheric filtration, nitrogen generators and more. Mikropor is an active CAGI member, and participant in the CAGI Refrigerated Compressed Air Dryer Performance Verification Program. “We are the exclusive global provider with performance verified ΔP of air treatment – both dryers and filtration, per se. By equipping our dryers with pre- and post-filtration, we can provide the third-party performance verified ΔP of the system to any end customer, auditor or any business requiring efficient and reliable compressed air treatment,” said Nitin Shanbhag, President, Mikropor America.

.jpg)

Mike Kinnucane, Nitin Shanbhag and Jeff Crutchfield standing next to the MCHILL-US Series Water Process Chiller at the Mikropor booth (left to right).

JORC Industrial, a global compressed air condensate management specialist, was celebrating their 30th anniversary and had a significant presence at the show as a Platinum Sponsor. On display at the JORC Industrial booth were its Level Sensed Drains (SMART-GUARD, MAG-11, NUFORS XF), timer drains (COMBO, OPTIMUM, TEC-11, D-LUX-N/O), EPA-Compliant SEPREMIUM 750 Oil-Water Separator (70 cfm up to 2,500 cfm), and more. JORC Industrial’s oil-water separators have useful features like a visual element life indicator that let you know when your elements need replaced and an overflow indicator to avoid messy spills.

Darren De Bie, Anthony Yacucci and Jan De Bie at the JORC booth (left to right).

Platinum Sponsor, Hertz Kompressoren reported the continued growth of their Charlotte-based U.S. operations. Stephanie Brockman told me they currently have several job openings available needed to support this growth. They were displaying their oil-free multiplex HS Series scroll packages which go up to 50 hp. They then showed me their new WAVE Series 3-stage, air-cooled, direct-drive, reciprocating, high-pressure booster compressor. The range is from 15 to 40 hp and with a pressure rating up to 580 psi.

Bob Groendyke, Stephanie Brockman and Mert Alpagut at the HERTZ KOMPRESSOREN booth (left to right).

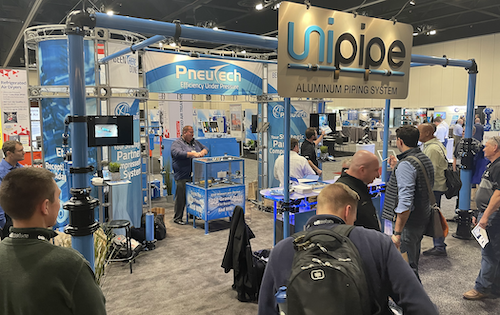

Platinum Sponsor, PneuTech, prominently displayed their UniPipe aluminum piping system. “Aluminum is the ideal material for compressed air piping, due to its lightweight, low cost and ease of installation. Unipipe is designed to minimize labor costs and ensure leak-free performance for decades of service,” said Derrick Taylor, Director of PneuTech USA. Unipipe is available in 13 sizes, from 3/4” to 10”. They offer four product options for different pressure ratings and applications, including Unipipe Air (for compressed air systems), Unipipe Nitro (for nitrogen and other inert gases), Unipipe Vac (for vacuum applications), and Unipipe HP (for high-pressure applications exceeding 232 PSI and up to 1015 PSI).

The PneuTech booth featuring the Unipipe Aluminum Piping System.

CEO Bruce McFee (far right) and the Sullivan-Palatek team were glad to see their distributors at the show.

John Temple, Patrick Lamon, Chad Gooding (G3 Industrial Solutions) and Charles Kowalyshyn at the Sauer Compressors booth (left to right).

The Altec AIR team announced new compressed air dryer technology coming in the 3rd quarter 2022!

David Sleeman, Luke Gigliotti, Carolyn Rorer, Scott Folsom, Shawn Duwal and Danielle Naser at the FS-Curtis and FS-Elliott booth (left to right).

Jon Jensen, Nathan Eisel, Aleksandr Shmushkin, Scott Minato and Rick Dunlap at the SMC Corporation of America booth (left to right).

Bill Kirkpatrick and Bill Duffel at the Applied System Technologies booth (left to right).

Mike Rigor and Allie Stanley at the Parker Hannifin booth.

Reed Lawless, Ray Parry and Stephen Parry at the Bay Controls booth (left to right).

Artem Vityuk, Noel Pipkin and Robert Duffin at the BASF booth (left to right).

Les Taylor, Theresa Hinkler, Madison Lester and Andy Freyer at the Kingston Valves booth (left to right).

Ryan Shaner, Jen Bessler, Rachel Pesnikov and Marc Schlaiss at the Midwest Control booth (left to right).

Erin Zimmerman and Alec Thompson at the Trace Analytics booth (left to right).

The New Technology EXPO Classroom

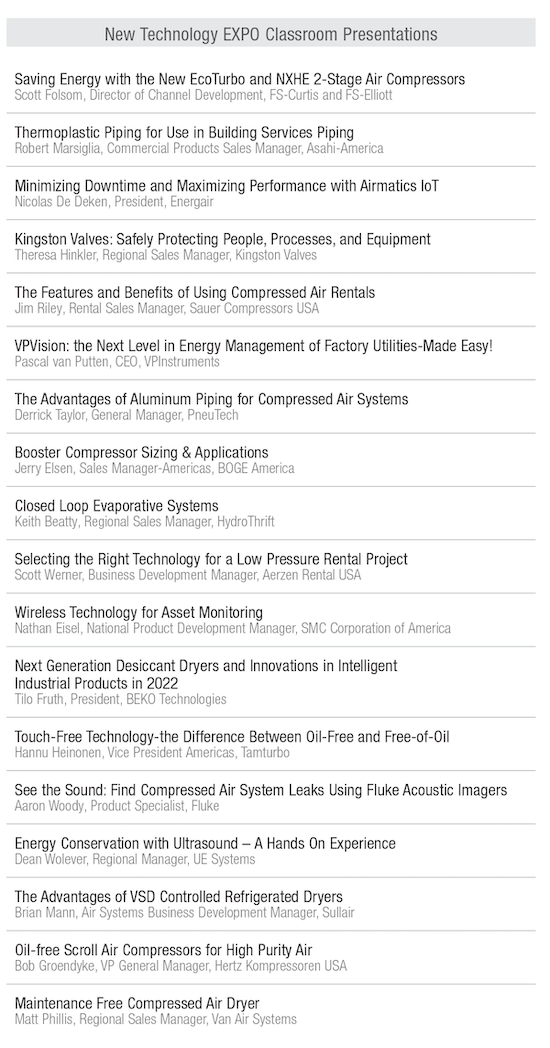

EXPO visitors also had the opportunity to wander in and out of the New Technology EXPO Classroom. From 1 to 5:30 pm each day, nine exhibitors had the opportunity to share their new technologies with EXPO attendees. Technologies featured included centrifugal air compressors, aluminum piping, thermoplastic piping, air compressor automation, air compressor and blower rental equipment, valves, flow metering, closed-loop evaporative systems, ultrasound leak detectors, refrigerated and desiccant dryers, and oil-free scroll air compressors.

Nicolas De Deken, President, Energair, presenting new air compressor automation technology, at the New Technology EXPO Classroom.

Tilo Fruth, President, BEKO Technologies, introducing new desiccant compressed air dryer products, at the New Technology EXPO Classroom.

The Daily EXPO $1,000 Energy Treasure Hunt RAFFLE!

The Daily EXPO \$1,000 Energy Treasure Hunt Raffle is designed to reward the people who make Energy Treasure Hunts in manufacturing plants happen! This is why only distributor sales engineers and service technicians, auditors/consultants/engineers and manufacturing plant personnel are eligible for the daily raffle prizes of Visa Gift Cards of (1) \$500 and (2) \$250. To be eligible, contestants have to visit the Sponsor Booths of the Raffle and get their Treasure Hunt cards stamped. Congratulations go to the following winners in 2021!

- Shawn Anderson, Ring Power Corp.

- John Bilsky, Gentex Corp.

- Clint Hill, National Compressor Services

- Matt Brockman, Atlantic Compressors

- Manuel Elizalde, Tunna Industrial

- Brian Coder, Tate Engineering

|

|

Shawn Anderson (Ring Power) and John Bilsky (Gentex), receiving their treasure chests, from Rod Smith, during the Daily EXPO $1,000 Energy Treasure Hunt RAFFLE (left to right)!

Save the Date: Atlanta, October 4-6, 2022!

The event was another success and we are looking forward to seeing everybody again October 4-6, 2022 at the Cobb Galleria Centre Atlanta! The location is in the exciting new area, north of downtown, connected to “The Battery” entertainment zone and the Atlanta Braves ballpark. Please save the date and plan on sending your sales engineers and maintenance staff for continuing education, certification and networking opportunities! For more information please visit https://cabpexpo.com or contact Bill Smith at email: bill@airbestpractices.com.