04/21/2020

Since the cooling needs of virtually every manufacturing plant differs, how can a facility manager determine which chillers, cooling towers, temperature controllers or other cooling equipment is right for their operation?

Chiller & Cooling Best Practices Magazine interviewed Peter Armbruster (Director of Sales and Marketing) and Bob Smith (Director of Product Management) at Thermal Care to gain insights into best practices used to accurately evaluate and assess a plant’s cooling needs and ultimately provide the solution best matched to the application.

Good morning! Tell us about Thermal Care

We’re an industrial process cooling equipment and systems solutions provider headquartered in Niles, Illinois. We’ve been manufacturing chillers and other process cooling equipment since 1969 for use in a wide range of industrial applications worldwide.

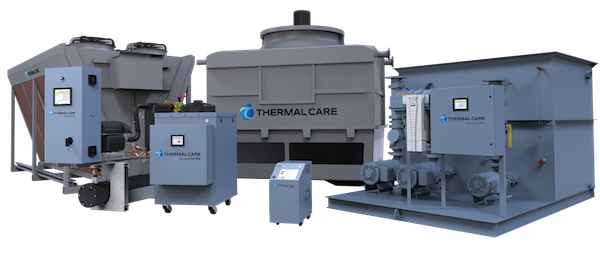

We offer central chillers, portable chillers, temperature controllers, cooling towers, and tanks. This includes standard models, as well as customized integrated systems. We excel at bringing all of the individual components that make up a complete cooling system together in a single portfolio. In addition, we have the engineering capacity and a deep level of expertise required to understand a facility’s processes and to determine the appropriate solution to meet their needs.

Thermal Care manufactures a complete line of process cooling solutions.

What’s the first step in accurately assessing a plant’s process cooling needs?

That’s what makes the job fun because there can be a whole host of things that determine the appropriate solution. You’re never putting the nut on the bolt every single day the same way, even if it is a single piece of equipment.

As with any business, we’ll start with the very basics to find out what the customer is looking for and asking key questions because there are so many variables involved. If the plant is in need of a single piece of equipment, such as a chiller, and the chiller will be cooling a single machine or process, we can formulate the appropriate solution fairly quickly without the need for a lot of technical detail. But even then, it’s about asking the right questions. We train our people to always take a step back, and ask, “What problem are we trying to solve?”

For example, a facility manager might say, “I need a 100-ton water-cooled chiller.” In that case, we start asking questions like, “Can you tell me about your cooling tower system?” And then we might learn they don’t have a cooling tower, which means what they really need is an air-cooled chiller because there’s no way to effectively cool a water-cooled chiller without a cooling tower system.

Or, the customer might say they need to do something relatively straightforward like providing cooling to their air compressors. That sounds fairly straightforward, but then we’ll always dig deeper. For instance, we’ll ask if there’s anything else in the plant that needs cooling. And they might say, “Oh yeah, I’ve got a vacuum pump over here that also needs cooling.” So now, we start to learn more about their entire cooling load and what they really need.

What we always do at the fundamental level is ask, “Where is the heat coming from?” Then the next question we want to answer is, “How do we want to get rid of it, while saving water or energy or whatever is most important for that facility?”

When we go beyond a single piece of equipment and get into plant-wide process cooling systems, we’ll get our applications engineering team involved and work hand-in-hand with the customer to go through a lot of detailed questions and answers. We’ll do quite a bit of legwork as part of a comprehensive evaluation to ensure we provide the right recommendation. Also, when a customer says, “I don’t know what I need,” we’ll get our applications engineering team involved.

Variable speed compressor packaged chillers with advanced PLCs can save up to 50% in energy costs versus conventional packaged chillers.

Chiller & Cooling Technology Monthly e-NewsletterWith a focus on Supply-Side Optimization, energy and Water Savings in industrial and commercial HVAC and process cooling systems are profiled. Case studies and technical articles focused on optimizing cooling towers, central plant chillers and process chillers. We also focus on building knowledge on refrigeration compressors and circuits. |

What are the main elements of a comprehensive process cooling system assessment?

We’ll look at the type of facility, the facility’s geographic location, the industry market segment, the production processes and cooling loads involved, and the location of the production equipment within the facility. Of course, with an existing facility we’ll also gather everything we need to know about the cooling system already in place.

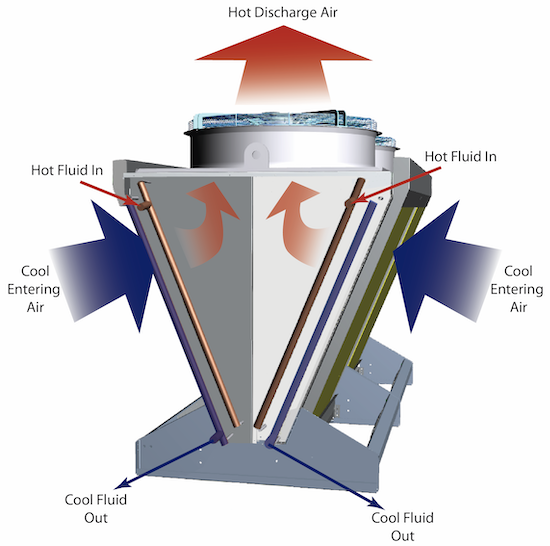

We will work up front to identify and understand the company’s organizational objectives. Maybe, for example, they’re highly interested in water conservation. That’s not always necessarily on the top of everyone’s list, but if it is, it might be as simple as recommending the use of a dry, adiabatic fluid cooler rather than an evaporative cooling tower since it saves water because it’s not exposing the process cooling water to the atmosphere.

Reduced energy consumption is another example and its often a high priority for many facilities. In this case, we’ll focus on solutions with energy-savings potential like chillers with variable-speed refrigeration compressors or free-cooling systems.

What also comes into play in the initial phase of an assessment is what a plant’s growth looks like. We always ask, “What is your five- or ten-year plan?” so that we’re taking that into account when designing a system.

All the while, understanding and evaluating the process to be cooled and any needs specific to that process is critical. This calls for an assessment of the heat loads to determine what each process or machines requires to function at peak efficiency. The customer’s market segment and processes to be cooled are instrumental in determining the required information and data we’ll gather when evaluating their needs and developing a solution.

Using the example of a fluid cooler to achieve water savings, we might find it’s not the best solution if the plant needs lower process water temperatures because the fluid cooler is limited by the temperature of the ambient air. The practical limit for process water temperature leaving the fluid cooler is typically about 10 °F warmer than the entering ambient air temperature. If a lower process water temperature is required, we’ll look at other options.

Fluid coolers use less water but are limited by the temperature of the ambient air.

What factors of the heat load do you evaluate as part of an assessment?

Our job is to ensure the plant is receiving the correct flow, pressure and temperature required, which in turn, enables the process cooling equipment to operate at its maximum efficiency.

We’ll analyze the cooling temperature requirements at the process, as well as the ambient temperatures. Some processes operate at very high temperatures, for example, which means the solution might call for the use of a different heat transfer fluid. In this case, the optimum heat transfer fluid might be a mineral oil.

Oftentimes, however, just lowering the coolant temperature isn’t necessarily the best way to achieve better heat transfer properties. You can recommend a chiller with a certain tonnage of cooling capacity, and that’s great, but you need to determine the appropriate pressure and flow required for the process because chiller temperature alone is only one facet to the overall solution.

Why are pressure and flow important when evaluating cooling options?

Pressures and flows are vitally important because they’re essential for proper heat transfer.

Within a heat exchanger, the right pressure is required in order for the heat transfer fluid to remove the proper amount of heat it as it circulates through the heat exchanger’s cooling channels. That requires an analysis of the heat load and a determination of the pressure drop across the heat exchanger.

Typically, the manufacturer of a machine that needs cooling will design the unit’s cooling channels based on a specific number of gallons per minute and pounds per square inch required for proper cooling. We’ll back-calculate what flow is needed for that particular piece of equipment to achieve the proper cooling rate.

Flow is crucial because heat transfer is actually due to mass flow, which happens in a couple of different phases. One phase is turbulent flow. This is basically when the heat transfer fluid is moving fast enough through the heat exchanger that it’s efficiently pulling heat away from the cooling channel surfaces. On the opposite end of the spectrum is laminar flow, which is when the heat transfer fluid travels slowly through the cooling channels. Laminar flow is less efficient than turbulent flow because it creates an insulation effect, which in turn, impedes the heat transfer process.

At the end of the day, we’ll use this data and perform calculations to determine the total cooling capacity needed and then start working through the options for transferring British Thermal Units (BTUs) as efficiently as possible, whether that means using different refrigeration compressor technologies on chillers, or a certain sized cooling tower, or another alternative.

How does your team acquire the needed data for comprehensive assessments?

By going through a lot of detailed questions and answers and doing a lot of legwork. Sometimes, we’ll gather data from each piece of equipment to be cooled within the facility, or the customer will provide us with that specific information. Or, there are times when we’ll need to do some research and talk to the manufacturer of a component to get the data necessary. Or, we’ll look at the amp draw to get a handle on power consumption. It’s often a combination of multiple factors to get us to that end result.

When it comes to industrial process cooling, our customers usually don’t hire consulting engineers to specify the appropriate cooling solution. Instead, most of them really rely on companies like ours to work through the assessment process with them.

Why do most plants look for outside expertise for help with assessments?

The challenge for most small- to medium-sized manufacturers has to do with limited engineering staff. Most of the engineering teams at plants of this size have their hands full since they wear many hats. It’s a huge challenge for them to be experts in all technologies, including process cooling solutions.

That’s where we come in. We live, eat and breathe process cooling technologies and that allows us to impart some of that knowledge and wisdom to our customers, which helps them to meet their goals for process cooling, as well as addressing their operational and business objectives.

Thank you, Thermal Care for your insights.

For more information about Thermal Care and its products and services, visit https://thermalcare.com/.

All photos courtesy of Thermal Care

To read similar Cooling System Assessment articles, please visit https://coolingbestpractices.com/system-assessments.