08/29/2024

It’s a universal truth that no person or machine is infallible, yet when we buy a product, we expect 100% reliability. This isn’t just in terms of avoiding a fault or breakdown, we expect the product to:

- Perform as advertised, so it works in real life as it does on paper

- Provide accurate product data for reliable system design

- Be compliant with regulations

To add to this, those making purchasing decisions for HVAC and refrigeration (HVACR) products can face a minefield. Not only do they have to deal with key factors such as installation cost and whole lifecycle cost, but selecting reliable, energy-efficient technologies is crucial as decarbonization and sustainability demands increase.

With a myriad of manufacturers and products to choose from, it’s important decision makers know about the free and helpful tools at their disposal. In this article, the independent third-party product certification body Eurovent Certification explains how to aim for excellence and safeguard against reliability risks by using products with proven performance.

Ian Butler, Business Partnership Manager at Eurovent Certification.

Underperformance Is a Hidden Issue

Even the best designed systems will underperform if real life product performance does not match manufacturer claims. Products that underperform can:

- Be non-compliant with regulations

- Use more energy

- Create a larger carbon footprint

- Incur high running costs

- Not meet end-user requirements

- Be more prone to faults and breakdowns

- Impact other parts of the system

- Result in penalties, litigation and reputational damage

How do you know which products to trust? Third-party product certification can mitigate risks by verifying manufacturers' claims, ensuring products perform as promised.

BAC Case Study: The Impact of Underperformance

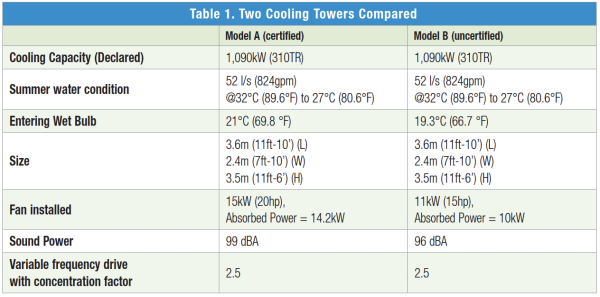

A new cooling tower is required for use in an industrial HVAC application, operating year-round, with a load variation from 100% in summer to 80% in winter. The cooling tower for this application would be selected for a summer condition to cool 52 l/s (824 gpm) of water from 89.6°F (32°C) to 80.6°F (27°C) at an entering wet bulb temperature of 69.8°F (21°C). The cooling capacity to be rejected would be 1,090 kW.

The decision maker has the choice between two cooling towers. Model A, is a certified cooling tower, with performance data independently verified. Model B is uncertified. Unknown to the specifier, its actual performance is 80% of the required duty if using the specified conditions. Therefore, Model B has supply water 2.2°F (1.2°C) warmer than designed and the installation will be penalized the entire year by the higher supply water temperature. It will for example, take a wet bulb of 66.7°F (19.3°C) to supply the required 89.6°F (32°C)/80.6°F (27°C) water temperatures.

Model B is available at a slightly lower price (approximately 10 to 15% cheaper). Note that the customer cannot tell Model B will underperform based on the dimensional data and face values for fan power and sound.

Performance at Design Conditions

Model A will perform to the specified design conditions as expected. Model B will have to operate slightly outside the design conditions to reach the 1,090 kW cooling capacity. Model B’s underperformance will impact the whole system, because:

-

The installed chiller will not totally stop due to excessive high pressure; due to the 2.2°F (1.2°C) warmer water the chiller will unload and capacity will suffer, however it will not fail. The final result will be some loss of comfort, or in the case of industrial applications, some slowdown of the production process will take place.

-

In typical Mid-European climates there will be less than 100 hours when the wet bulb temperature is higher than 66.7°F (19.3°C), spread over a few summer days.

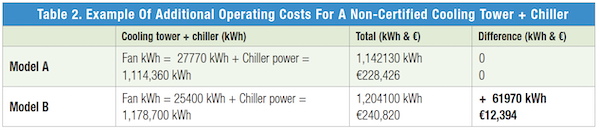

The underperformance may seem slight. In fact, there may be several years of bad summers, where design water temperature conditions are never exceeded. So why is it a problem? The answer can only be found if we look at the annual economic impact. By comparing Model A and Model B, we see the fan kWh requirement for Model A will be 27,770 kWh and for Model B it will only be 25,400 kWh, due to the smaller fan motor. However, look at the electrical energy needed for the chiller: For Model A, we need 1,114,360 kWh, but for Model B the chiller requirement goes up to 1,178,700 kWh, which is almost 6% more. Therefore, if we add up the chiller and fan kWh, Model B needs 5% more electrical energy on an annual basis.

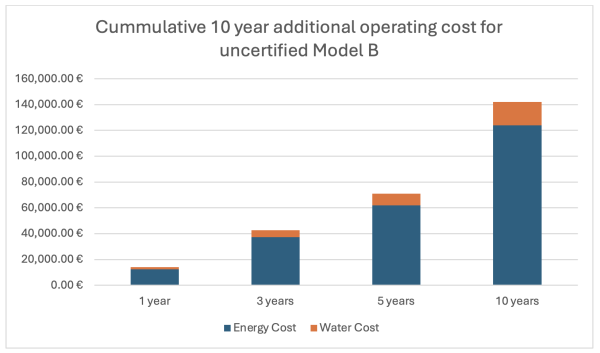

Example of additional operating costs for a non-certified cooling tower + chiller = +$13,517 (+€12,394)/annum at a modest $0.22 (€0.20)/kWh:

Note that energy prices have fluctuated wildly over the last couple of years. The increase kWh rate, at its peak in January 2023, would have seen a rate of $0.55 (€0.50)/kWh = +$33,792 (+€30,985)/annum!

But it doesn’t end there. In addition to electrical costs, there is more water consumption for Model B because the chiller has to work harder, hence more waste energy has to be dissipated and more water will evaporate. In our example, Model B will consume per annum 500m³ water more. If we take the modest cost for water supply, sewage and chemicals $3.94/m³ (€3.61/m³), this adds another $1,969 (€1,805) per year.

The total additional annual operating cost for water and electricity for the system with Model B is $15,485 (€14,199). This is around half the initial cost of the new cooling tower, and shows the small installation price advantage is a false economy. Long term, Model A offers a more energy efficient, effective, reliable and cost-friendly choice.

Certified thermal performance testing guarantees performance and removes both risk and guess work to obtain system economics.

Eurovent Certification: The Ultimate Safeguard for Product Decisions

Certification finds the truth of a product, creating trust between all players in the industry. However, not all certifiers or certification schemes are equal. Manufacturers can choose from a range of programs delivered by laboratories or certification bodies, so it’s always wise to understand what each offers. With over 40 programs, including the flagship Eurovent Certified Performance mark, Eurovent Certification is a world leader in certifying HVACR product performance.

Independent and Impartial Certification

As a third-party certification body, Eurovent Certification works independently of manufacturers (first party) and their customers (second party), with no bias toward or against any other party. The value of third-party certification is that product performance is verified by an independent body without a vested interest. In fact, Eurovent Certification is obliged by its ISO IEC 17065 accreditation (by COFRAC*) to provide certification programs that are non-discriminatory and impartial.

Fair But Rigorous Certification Process

The Eurovent Certified Performance mark cannot be bought. All products are rated against a common set of criteria. Using state-of-the-art evaluation protocols, products must pass stringent checkpoints to gain certification. All manufacturers are treated equally, with all units going through the same route and process, wherever in the world they are manufactured. Impartiality standards are kept high as manufacturers and laboratories have no direct contact, keeping the process clear of any bias.

Enhanced Testing and Evaluation

Eurovent Certified Performance is elevated above laboratory testing alone, as Eurovent Certification also:

- Audits manufacturing site(s)

- Undertakes selection software checks

- Analyses the submitted data for technical credibility and continuity

- Undertakes yearly surveillance monitoring

- Every model in range under a certify-all program must be submitted and pass the certification criteria; this ensures quality throughout the range, and not just the flagship model

Crucially, the products tested can be taken from the production line, factory stock or point of sale, ensuring the product tested is the same as those leaving the production line.

Certified Software

Most Eurovent Certified Performance programs include selection software certification, meaning it’s not just the products themselves that are certified, but the tools to select them, as well. This offers reliability and reduced risk for system design, especially in applications where there is a 0% tolerance for modelling.

Compliance with LEED Building Scheme

Where a specified drift rate is required to meet LEED 0.002%, Eurovent certified products provide assurance of compliance and product performance, reducing the risk of litigation. Additionally, the Eurovent Certified Performance program for cooling towers measures pressure drop of the power input and power absorbed by the fan during operation, giving further assurance of performance.

Customer Confidence

For specifiers, buyers, installers and end users, Eurovent Certified Performance provides peace of mind that chillers, cooling towers and other certified HVACR products will perform as expected.

Certification Encourages Innovation and Competition

Manufacturer R&D teams can use certified data to provide a reliable baseline for product development, allowing them to evaluate the effectiveness of their innovations. Certifying new or improved products also creates confidence in new technology.

Quality Control

For manufacturers, Eurovent Certification’s factory audits aid in-house quality controls, ensuring standards on the production line remain high. Products are audited not only when initially certified, but most Eurovent Certified Performance programs demand annual audits, as well.

Finding Certified Products

Eurovent Certification provides free, 24/7 access to transparent, accurate, universally understood performance data via its online Certified Product Directory. Whether you are considering a product new to the market, a brand you haven’t used before or want to check the credentials of your “go to” choice, you can use certified data to confidently compare products and make informed decisions.

Search HVACR products by product family, type, brand, model name or certificate number. If a product isn’t there, it isn’t certified. Visit https://www.eurovent-certification.com to let the power of proven performance rule out reliability risks.

* Eurovent Certification is accredited as a certification body compliant with ISO/IEC 17065:2012 standard by COFRAC (Accreditation N°5-0517, scope available on https://www.cofrac.fr.)

About the Author

Ian Butler has 37 years’ experience in HVACR, with 14 of those at Eurovent Certification. He is Program Manager for the Eurovent Certified Performance programs for both cooling towers and drift eliminators, and acts as U.K. Partnership Manager.

About Eurovent Certification

Established in 1993, Eurovent Certification is recognized as a world leader in voluntary, third-party product performance certification. Eurovent Certification certifies over 40 HVACR programs, including the flagship Eurovent Certified Performance mark, the NF mark, QB mark, Keymark, CE Trade Mark and MCS for Heat Pumps. For more information, visit https://www.eurovent-certification.com.

To read similar Cooling Tower Technology articles, visit https://coolingbestpractices.com/technology/cooling-towers.

Visit our Webinar Archives to listen to expert presentations on Cooling Tower Technology at https://www.airbestpractices.com/webinars.