07/21/2017

Chiller & Cooling Best Practices Magazine interviewed Paul Heston (General Manager) and Tom Strock (Chief Engineer) from Hydrothrift Corporation.

Good morning. Could you provide an overview of the American National Standard for Emergency Eyewash and Shower Equipment (ANSI Z358.1)?

Good morning. In a nutshell, where workers are exposed to harmful chemicals, they must have eyewash and safety shower stations to decontaminate themselves in the event of a spill or splash. A variety of industries, including petrochemical, chemical, metal fabrication and laboratories, must plan for this contingency. The ANSI Z358.1 Standard specifies the water used for these purposes must be tepid or within a site-specified range. This means in colder climates, water must be heated, and in hotter climates water must be cooled.

In some very hot climates reaching temperatures like 122 °F (50 °C), the water available will be much too hot to use. In addition, this hot water could activate chemical substances and make things significantly worse for the victim of an accident. In colder northern climates, cold water could cause hyperthermia to the user. OSHA and ANSI decided this was an issue requiring attention and ANSI Z358.1 establishes requirements for eyewash and safety shower stations.

Awareness of this safety issue has created demand for our Safety Shower Water Tempering Systems. These systems are custom designed to control safety shower water temperature for various ambient conditions utilizing custom engineered chillers and heaters.

What are some details in ANSI Z358.1 impacting your Safety Shower Water Tempering Systems?

The ANSI Z358.1 Standard is published by the International Safety Equipment Association and can be purchased from ANSI at https://webstore.ansi.org. It’s a 28-page Standard but here’s a brief sampling of items in the Standard impacting our safety shower water tempering systems. For Emergency Showers:

- Minimum volume of flushing fluid (20 gallons per minute) for a minimum specified duration (15 minutes).

- Flushing fluid supply flow pressure (30.5 psi).

- Installation will permit accessibility within a specific period of time (10 seconds).

- If freezing conditions are a possibility, freeze-protected equipment must be used.

- Deliver tepid flushing fluid. Facility safety professionals on-site should be consulted for specific temperature ranges if required.

Do engineering firms design centralized or decentralized Shower Water Tempering systems?

They design both. If it’s a smaller facility requiring a single eyewash or safety shower station, they’ll simply specify a 1-ton (or smaller) individual chiller for that one station.

In a large chemical plant requiring fourteen (4 to 36) eye wash stations, they will specify and design a centralized shower water tempering system. This cooling (or heating) system will temper water for all the shower stations. Tempered water is continually circulated through the piping to ensure consistent temperatures, within the specified ranges, at the eyewash and shower stations.

A 1500 to 2000 gallon storage tank can take the chiller size (in this hypothetical example) down to a 3 or 8-ton chiller depending on the ambient heating.

How do you assist engineering firms with engineering energy and water savings into the specifications?

The application engineering support we provide varies on the knowledge at the engineering firm. We’ve seen firms with everything designed while others contact us with very little information and need us to lay out the system for them efficiently.

We’ve seen some engineering firms and owners design for simultaneous use. As a result they have large flow rates of water being consumed. Some engineering firms say they need our system to temper the water from 122 °F (50 °C), down to tepid temperatures at whatever their makeup flow rate is.

For example purposes, this specification approach will result in a 100-ton chiller or more because they haven’t incorporated a storage tank into the system design. Our application engineers identify the activation time of 15 minutes in the ANSI Z358.1 Standard, and typically they will have a limit of two (2) safety showers running at the same time. So if a system has (2) safety showers operating each at 20 gpm for 15 minutes, 600 gallons of water will be withdrawn from the tank and 600 gallons of potentially very warm makeup water will be added. By sizing the tank sufficiently large, we can maintain the temperature within the allowed temperature ranges and then use a smaller chiller to reduce and then maintain the water temperatures over a longer period. With the tank’s thermal storage, a 3 to 8 ton chiller is adequate in contrast to an 80 ton chiller if the makeup water was cooled instantaneously. This specification strategy can greatly reduce the capital and operating costs of chillers.

That’s a big difference! Any other issues relating to storage tank selection?

The big thing is for owners and engineering firms to properly size the tank, to prevent the over-sizing of the chiller. Often some engineering firms are set in their ways and don’t want to go back to the owner and change the specification. The earlier in the process they contact us, the better.

The ANSI Z358.1 Standard also establishes the requirement of tanks needing to be able to support the safety shower requirements if the makeup water is cut-off or unavailable. Design engineers will make sure the tank is large enough and has enough thermal inertia associated with it – to handle a big demand event. You hopefully have enough cooled water in the tank. It’s not a real difficult calculation to go through the thermal system. The engineering firms mostly do this process engineering work and determine the tank size.

In some cases we provide the tank. In other cases, the tank is provided by the owner or the engineering firm. Often these are difficult items to ship as they can be 15 to 20 feet tall. The tank is insulated as well as is all the piping in the safety shower units. Similar to a commercial building, they are continuously circulating a small volume of flow, about 1 gpm, to provide an instant temperature response to demand. Insulation is normally installed at the job site as part of the final assembly and commissioning process.

Please describe your work with chemical and petrochemical plants classified as hazardous and in high ambient temperatures?

We have developed a particular expertise in custom designing systems for high ambient temperatures in what are often applications classified as electrically hazardous or potentially explosive. We often work on tough jobs that others can’t (or prefer not to) work on. We welcome custom specifications.

In very high ambient temperature locations, sun shields on electrical panels may be required.

We supplied forty-four (44) systems for the world’s largest integrated petrochemical plant recently completed in Saudi Arabia. The Engineering, Procurement and Construction (EPC) firm worked with us to optimize the system design requirements which resulted in savings of about 30%. The specified ambient design temperature of 131°F (55 °C), the “chilled” tepid water between 68 and 95 °F (20 and 35 °C), 122 °F (50 °C) makeup water to fill the tank, and the hazardous electrical areas eliminates off-the-shelf commercial refrigeration systems and isn’t what off-the-shelf commercial refrigeration components are set up for. We have to do some things a little differently to make sure the refrigeration compressor is getting proper return temperatures and pressures, to ensure longevity. We normally use small semi-hermetic scroll refrigeration compressors - and they aren’t designed for chilling water to a warm 70 °F.

We typically operate at high condensing temperatures of 155 °F (68 °C) for the 131 °F (55 °C) ambient dry bulb temperature. We then utilize refrigeration head pressure controls to maintain relatively high condensing temperatures. We use R134a refrigerant. Refrigeration compressors and evaporators are sized accordingly as we try to keep refrigeration compressor suction and discharge pressure within it’s envelope. Crankcase pressure regulators and desuperheat expansion valves prevent excessive return temperatures and pressures.

Special air-cooled condensers designed for 131 °F (55 °C) ambient temperatures and Class 1 Div 2 fan motors, Heresite-coated coils for corrosion protection.

The classified hazardous locations limit what we are allowed to do with electrical controls. Our electrical controls are very simple because they are often in Class 1, Div. 2 explosive hazard locations. We can’t use variable frequency drives and transmitters on refrigeration compressors and avoid these on purpose. Due to the remoteness of the locations, we also focus on using commercially available refrigeration tools and components such as thermal expansion valves, desuperheat valves, and hot gas bypass valves.

What kind of evaporators are used to maximize performance and worker safety and comfort?

That’s a good question because we not only have to design for thermal performance, we have to ensure water quality for the shower. Mounted on the safety shower water tempering system skid, a double wall heat exchanger transfers heat carried by the safety shower water to the closed loop coolant system. Designed and manufactured to ASME pressure vessel code, the plate and frame or brazed plate heat exchangers are engineered and built for the most efficient operation and heat transfer.

Very high efficiency evaporators used with double wall laser welded plates to isolate refrigerant from potable water.

The double wall design ensures any leaks do not contaminate the circulating safety shower water. The double wall is used on systems with potable water-to keep cooling medium from getting into potable water.

Sometimes we also isolate the heat exchanger and refrigeration system with a closed loop propylene glycol system. With a propylene glycol system we can often operate the refrigeration system over a wider range of capacity and allow it to operate more efficiently at typical ambient temperatures. Without the propylene glycol system, we must concern ourselves with the possibility of freezing the water in the evaporator when ambient temperatures are lower and this then requires us to spoil capacity and maintain suction pressures with hot gas bypass valves.

Chillers usually don’t have to run in the winter, but if it’s too cold, we’ll also place a heating ciruit to add heat when needed.

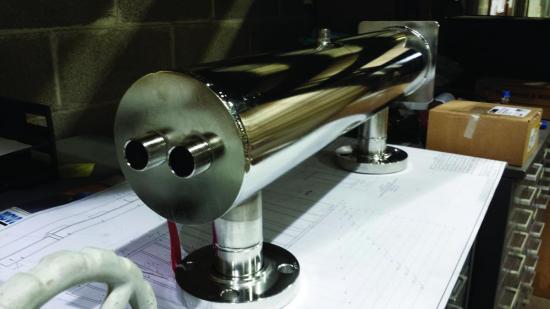

Last but not least, some customers will request a UV sterilizer utilizing ultraviolet germicidal lamps to destroy microorganisms in the circulating safety shower water. The UV sterilizer includes quartz glass sleeves inside a stainless steel sterilizer chamber, high intensity ultraviolet lamps, lamp intensity sensor, and a UV controller and monitor.

Ultraviolet disinfection chamber renders microbes harmless

What provisions are designed in for maintenance?

There are bypass valves around the chiller, pumps, ultraviolet sterilizing equipment and other components - so maintenance can be done. Skids may have multiple pumps, with 100% redundancy and bypass valves. The pumps can range from commercial stainless steel water pump to an ANSI frame mounted pump. Customers indicate their preferences with a pump specification.

Most engineering firms and owners are willing to work through specs and consider alternatives if there’s sufficient motivation. We are happy to work with them on designing custom engineered solutions.

There are bypass valves around the chiller, pumps, ultraviolet sterilizing equipment and other components - so maintenance can be done.

Thank you for your insights.

To learn more about Safety Shower Water Tempering Systems visit www.hydrothrift.com, email sales@hydrothrift.com, tel: 330-837-5141.

To read more Cooling Technology articles visit http://coolingbestpractices.com/technology.